Aerogel

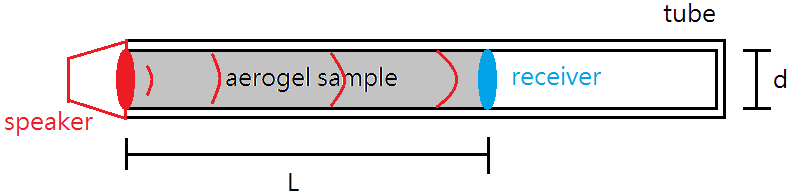

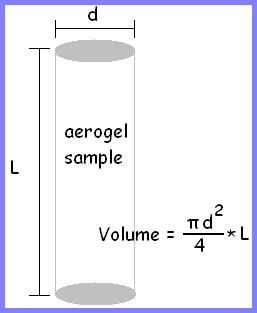

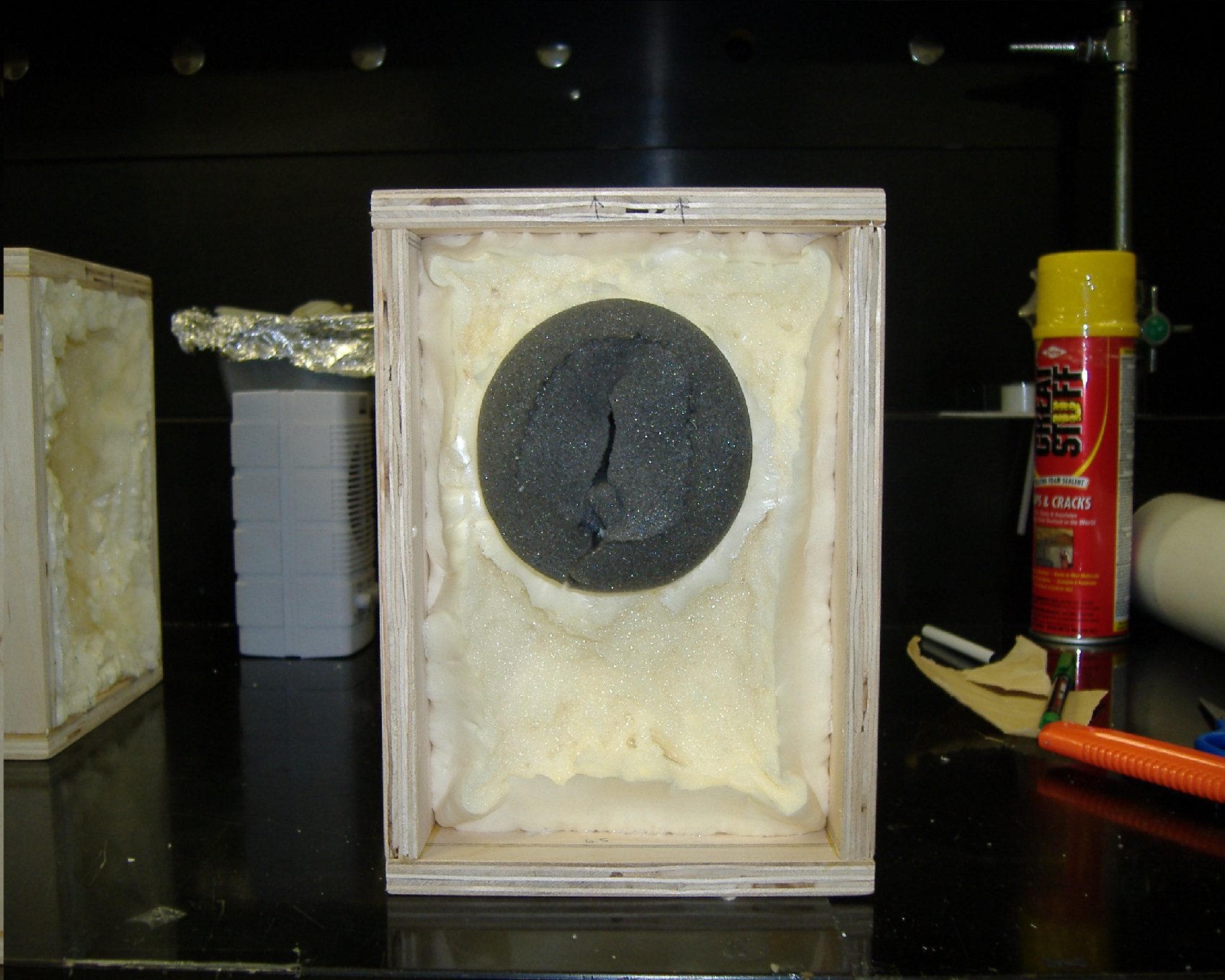

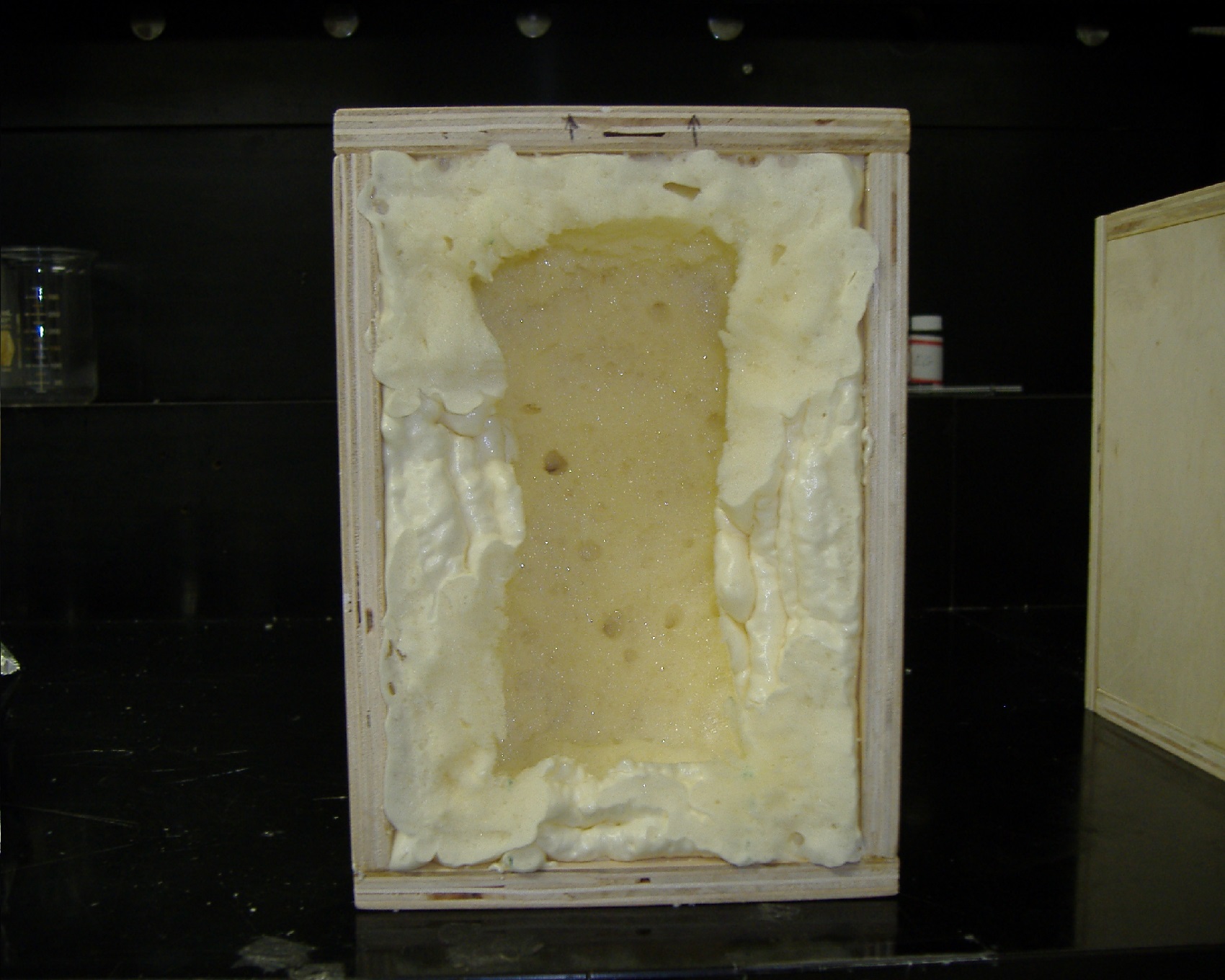

Cross-linked silica aerogels exhibit low density, low thermal conductivity, and low dielectric constant properties. They are intriguing candidates for a variety of thermal, optical, chemical, and electronic applications. As sound waves travel through porous structures in mineral wood, individual fibers vibrate, transforming the incoming acoustic energy into heat energy. It is surmised that aerogels may behave in a similar fashion. However, aerogels can be made of different polymer chain lengths and silica precursors, both of which impact the morphology. To determine the aerogel most suitable for sound insulation, it is important to obtain a relationship between each of these properties and their acoustic behaviors.