Solid-State Ammonia Sensors

Dialysis machines maintain the body's chemistry by filtering metabolic waste such as urea from the blood and regulating the concentration of necessary sodium and potassium ions. A Sorbent hemodialysis machine, unlike the conventional single-pass dialysis design, recycles and reprocesses the spent dialysate using a Sorbent cartridge. The cartridge contains zirconium compounds that bind and release chemicals, and an enzyme, urease, which converts urea into ammonium and carbonate ions. As dialysis process continues, the cartridge becomes saturated with ammonia. Therefore an ammonia sensor is required at the downstream of the cartridge to determine its concentration levels in the effluent stream.

Motivation

A kidney dialysis machine provides a critical function of emulating a healthy kidney for acute and chronic kidney failure patients. As dialysate is reprocessed and recycled the concentration of toxic chemicals such as NH3+ rises in the effluent stream. The FDA mandates that [NH3+] < 20ppm per 30 minutes of dialysis. The concentration is monitored via an ammonia sensor. The purpose of the dialysis system is to provide patients affected by chronic and acute kidney failure with easy and convenient therapy. The current system provides an option for at-home dialysis care for patients. However, there are areas for improvement in the ammonia system apparatus. Major areas of focus for this project are functionality, reliability, cost, ease of implementation, and safety.

Project Goals

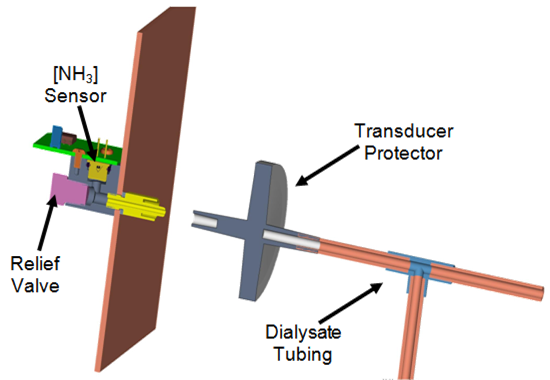

The current ammonia sensor is a pH sensitive indicator. It must be replaced after every use, and it has multiple areas of potential failure. The focus of this project was to evaluate, select, and implement a solid-state ammonia sensor within the current dialysis machine at Renal Solutions, Inc.

Background Research

Other ammonia sensor design alternatives such as electrochemical and infrared sensors were compared. Click HERE for design alternative comparison details.

Prototype